compression test buckling|critical load buckling calculator : OEM Slender or thin‐walled components under compressive stress are susceptible to buckling. Most people have observed what is called “Euler buckling” where a long slender member subject . webAmouranth Tube and other famous pornstars at TubePornstars.com. TubePornstars is one of the most complete pornstar databases you will ever find!

{plog:ftitle_list}

webA palpitação surge como uma pulsação forte ou batedeira no peito. Ela aparece de repente, causando a sensação de que o coração vai sair pela boca. Geralmente, não é percebida como uma dor e, sim, como um .

web compression buckling

One of these is the danger of (plastic) buckling, particularly if relatively large strains (>~10%) are to be created. In order to avoid this, the aspect ratio (height / diameter) . In tension, the failure is caused by an overload of the fibres, while in compression we see micro-buckling of the individual fibres. This micro buckling is due in part to the .Thus, to increase the comparability between experimental studies, the following guidelines for test conditions and procedures in buckling experiments with composite shells, as well as the .

A fixed end condition results in an effective length for buckling that is less than the actual length of the column, by as much as 50 %. Scope. 1.1 This test method covers the .

Slender or thin‐walled components under compressive stress are susceptible to buckling. Most people have observed what is called “Euler buckling” where a long slender member subject .

Composites Test Fixtures – Compression | Anti-Buckling-2 www.instron.com Worldwide Headquarters 825 University Avenue, Norwood, MA 02062-2643 USA Tel: +1 800 564 8378 or +1 781 575 5000 European Headquarters Coronation Road, High Wycombe, Bucks HP12 3SY, UK Tel: +44 1494 464646Note that N has been de ned as positive in compression. Therefore the plate will be compressed in the x-direction and will expand laterally in the y-direction because of the . Upon compression, the buckling pattern has a form shown in Fig. (11.6). Again, there are no relative rotations at the intersection line of .NASA TN D-5561: Buckling of Stiffened Cylinders in Axial Compression and Bending – A Review of Test Data, 1969 NASA CR-124075: Isogrid Design Handbook, 1973 . Figure 4-1: Buckling coefficients for simply supported isotropic circular cylinders subjected to axial

11.7 Compression buckling of thin rectangular plates. Consider the perfectly flat plate subject to a longitudinal compressive force of magnitude P x applied in a spatially uniform manner along edges x = 0 and x = a, as shown in figure 11.24.The equilibrium response of the plate in linear theory is that of pure compression in the x-y plane with no out-of-plane .

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and .Stability and Buckling Readings: BC Ch 14 Learning Objectives Understand the basic concept of structural instability and bifurcation of equilibrium. Derive the basic buckling load of beams subject to uniform compression and di erent displacement boundary conditions. Understand under what conditions structural design is limited by buckling .

where L eff is the effective length and L is the actual unsupported length of the column. For example, the theoretical effective length of a fixed-free column is 2L.The fixed-free column is twice as susceptible to buckling as a pinned-pinned column, such that the fixed-free column is effectively twice as long as a pinned-pinned column with the same material and geometry .which are prone to buckling under critical loads, such as axial compression, bending and torsion as well as combinations of those load cases [1, 2]. Due to the sensitivity of the buckling load to a variety of different influencing factors, there is a significant .In a compression test, there is a linear region where the material follows Hooke's law. . In compression metals fail from buckling/crumbling/45° shear which is much different (though higher stresses) than tension which fails from defects or .mode is called buckling, and it is an example of an elastic instability. The objective of this laboratory is to introduce students to the buckling test and to evaluate the ff that specimen length has on the failure load. Before the lab, students should compute the theoretical failure loads for each specimen using Euler’s equation for column .

The open-hole compression fixture was originally developed by Boeing and is outlined in Boeing specification BSS 7260. The test specimen is rectangular with a central hole. The fixture consists of a pair of interlocking plates that guide and prevent the specimen from buckling under the applied compressive load. Buckling is a phenomenon under which a member can suddenly fail due to excessive compressive load.The load at which the member fails is known as the critical load, F c r i t F_{crit} F cr i t or F F F.The buckling causes a reduction in the axial stiffness of the column that results in displacement and rotations having catastrophic consequences.

how to understand buckling

Example - A Column Fixed in both Ends. An column with length 5 m is fixed in both ends. The column is made of an Aluminium I-beam 7 x 4 1/2 x 5.80 with a Moment of Inertia i y = 5.78 in 4.The Modulus of Elasticity of aluminum is 69 GPa (69 10 9 Pa) and the factor for a column fixed in both ends is 4.. The Moment of Inertia can be converted to metric units likeComposite compression testing methods provide a means of introducing a compressive load into the material while preventing it from buckling. Compression tests are performed for composite materials that are in the form of a relatively thin and flat rectangular test specimen such as laminate panels.Compression test on a stocky column (a), buckling test on a column with a buckling length of 3'600 mm (λ = 62.3) (b), displacement sensors to measure vertical deformations in the columns (c) and .12 Buckling Analysis . Those material properties are determined by axial tension tests and axial compression tests of short columns of the material (see Figure 12‐1). The geometry of such test specimens has been standardized. Thus, geometry is not specifically addressed in defining material properties, such as yield stress. .

In the compression test, a standardized specimen is loaded under compressive stress until it breaks or until a first crack appears. . The maximum height of the sample is twice the diameter to prevent the sample from .

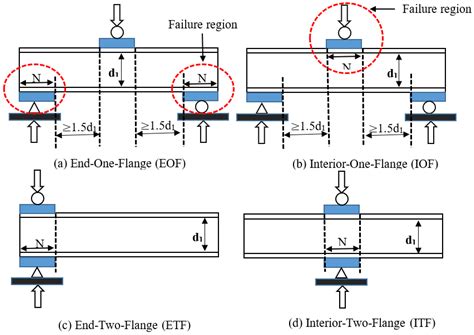

local yielding, web crippling, web sidesway buckling, web compression buckling, and web panel zone shear. The provisions for web compression buckling apply to a pair of compressive single-concentrated forces or the compressive components in a pair of double-concentrated forces, applied at both flanges of a member at the same location.374015354-Compression-Test-Lab-Report.docx - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. 1. The document describes a compression test experiment to investigate crippling of beams with different slenderness ratios. 2. The experiment measured variables such as force and slenderness ratio for different PASCO I . Standard Test Method for Axial Compression Test of Reinforced Plastic and Polymer Matrix Composite Vertical Members E2954-15R22 ASTM|E2954-15R22 . Note 1: The effective length of the column with respect to buckling is affected by the end conditions. A fixed end condition results in an effective length for buckling that is less than the actual .Buckling is identified as a failure limit-state for columns. Figure 1. Buckling of axially loaded compression members • The critical buckling load Pcr for columns is theoretically given by Equation (3.1) Pcr = ()2 2 K L π E I (3.1) where, I = moment of inertia about axis of buckling K = effective length factor based on end boundary conditions

If a buckling analysis is performed, SkyCiv Structural 3D warns of a buckling factor of 0.98, indicating that the structure is buckling (the factor is less than one). In fact, the buckled shape (shown in red on the right of the image below) shows that the long columns at the base are buckling. Bae and Huh proposed a spring-loaded clamping device to suppress T-buckling for the tension/compression test. The strain in the gauge region was measured by using a digital image correlation (DIC) method to overcome the structural problems associated with the application of conventional contact-type extensometers during the test. Such a .

Buckling is one of the major causes of failures particularly in slender columns. Buckling is caused by the failure in compression due to the material strength and stiffness properties. Different support reactions buckling load can be calculated using Euler's Equation and tested experimentaly in a laboratory strut testfailures are all termed buckling. 3.2.2 column—a compression member that is axially loaded and that may fail by buckling. . 6.1 Testing Machines—Machines used for compression test- A test method is described to experimentally investigate curved stiffened composite panels with respect to their buckling and post-buckling behavior up to collapse.

The compression test specimen is comparatively simple in shape, and the length of the test piece should not be too great, because it is necessary to avoid buckling. The compression test specimen either a cylinder with a ratio of length to diameter L/D < 2 to avoid non-axial motion, or the specimen may be in the form of a cube.

WEBEnter the code displayed on your device to connect to your Epic Games account. Learn more

compression test buckling|critical load buckling calculator